Iprojekthi yokuhlela ngokuzenzekelayo yamatayara agqityiweyo kwi-Shengshitailai Rubber iqonda i-automation kunye nolwazi lomkhondo wokukwazi ukuthutha, ukuhlenga, ukupakisha, ukugcinwa kunye nokuhanjiswa, kunye nokuphucula ngokuthe ngqo ukusebenza kakuhle kunye nokunciphisa iindleko zokusebenza kumashishini.

Ukuze ulungelelanise nophuhliso lwamashishini kunye nemfuno yeemarike, kunye nokuphucula ukusebenza kakuhle kwemveliso kunye nokunciphisa iindleko zabasebenzi, kwi-2015 Qingzhou Shengshi tailai Rubber Company (apha emva kokubizwa ngokuba yi "Sheng Tai") yagqiba ukuveliswa kweeseti zezigidi ezili-12. Ukulungiswa kwetayara eligqityiweyo ngokuzenzekela ngokuqhubekayo kunye neprojekthi yokubonisa kunye nesiqingatha sonyaka, ekugqibeleni qinisekisa isisombululo sokunikezelwa okupheleleyo kokugcinwa kwetayara okugqityiweyo kunye nokuhlelwa kwenkqubo yokudibanisa.

Shengshi Tailai Rubber

Inkqubo yokuhlela ezenzekelayo yamatayara agqityiweyo

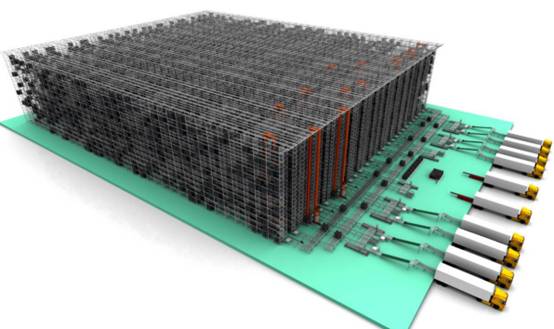

Iprojekthi yokuhlela ngokuzenzekelayo igubungela indawo emalunga ne-21000 yeemitha zesikwere, utyalo-mali olupheleleyo malunga ne-200 yezigidi ze-RMB, iprojekthi ye-Shengtai yokuhlela ngokuzenzekelayo iquka ukuhanjiswa okuzenzekelayo okuhlakaniphile, ukuhlelwa, ukupakisha ngokuzenzekelayo, inkqubo yokugcina ngokuzenzekelayo emva kokubhaqwa. Ngaphantsi kokufezekiswa kwenkqubo yolwazi lwe-ERP oluzenzekelayo, inkqubo ehlakaniphile kunye nengenamntu, imveliso yonyaka ye-12 yezigidi zeesethi zamatayara ihlangabezana nemfuno ye-Shengtai yexesha elide kunye nophuhliso.

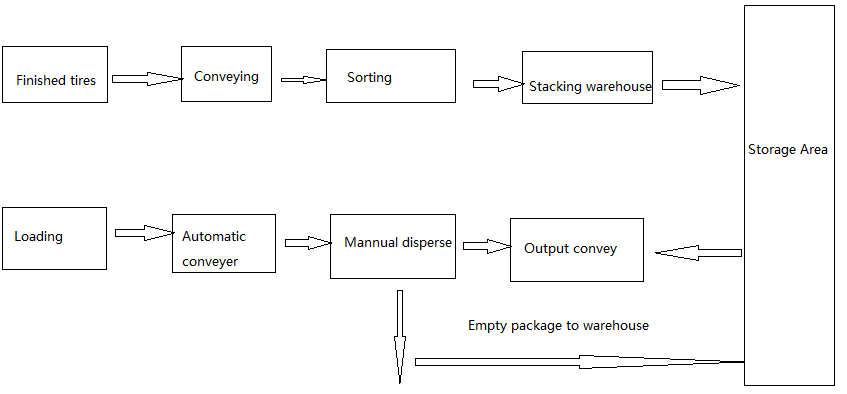

Iskimu sisebenzisa i-rack edibeneyo yokugcina, i-tones ye-14 iyonke, i-14 ibeka ngaphezu kwe-30 yeemitha ze-stacker, i-inventory enkulu ye-50400 pallets. Imveliso ithuthelwa kwindawo yokugcina impahla kumgangatho wesibini, ngenkqubo yokuskena yepanoramic yeemveliso eziqeqeshiweyo kunye neemveliso ezingafanelekanga zokuhlela ngokuzenzekelayo, emva koko i-robot ye-automatic palletizing igcinwe ngemigca yokudlulisela ithunyelwe kwindawo yokugcina ngeeseti ezili-14 zomatshini we-stacker, kumgangatho wokuqala. yetayara egqityiweyo ngomatshini we-roller wekhonkco, i-telescopic belt conveyor kunye nezinye izixhobo zokuhambisa ukugqibezela ukuhanjiswa.

Itshathi yenkqubo yeprojekthi iyonke

1. Ugcino lweemveliso ezigqityiweyo kwindawo yokugcina impahla

Ivili eligqityiweyo leworkshop livavanywa ngumatshini wokuvavanya onamandla. Ukuba udlula uhlolo, uthuthelwa kwindawo yokuhlela kumgangatho wesibini wendlu yesitora ethe nkqo ngepaseji. Amatayara aneziphene ahanjiswa kwindawo yokulungisa. Amatayara afanelekileyo emva kokulungiswa kwakhona adlule kumgca wepaseji ukuya kwindawo yokuhlela imigangatho emibini.

Umgca wokuhlela ku-2ndindawo yokuhlela umgangatho ihlelwe ngokweenkcukacha kwi-12 yokuhlela izibuko, kunye nerobhothi yaseLongmen ilayisha ngokuzenzekelayo amatayara kwindawo echongiweyo yedesika yokugcina ehambayo. Xa itayara elinye lifunjwe phezu kwesipaki kwiqonga logcino oluhambahambayo, irobhothi yaseLongmen ithwala yonke imfumba yamatayara kwindawo echongiweyo kwithala leencwadi laseLongmen. Ngokuhambelana nomyalelo wedatha ye-WMS, i-robot yaseLongmen iphethe isitakhi samatayara ahambelana nenombolo yesitaki kwi-tray engenanto. Emva kokuba izitya ze-tray zokugcina ze-RGV zihanjiswe kwikhompyutheni echaziweyo, i-stacker yokuphatha kwi-shelf yempahla ekhethiweyo.

A: ukuhlela ukuphathwa okungaqhelekanga: umatshini wokuhlela uxhotyiswe nge-outlet engaqhelekanga yokuphuma, kwaye itayara eligqityiweyo lifakwe kwi-port yokuphatha engaqhelekanga yincwadana kwaye igcinwe kwindawo yokugcina impahla.

B: kwinkqubo yokugcina isitakhi sokubonwa kwembonakalo kunye nokuphononongwa kwekhowudi yebha, njengemeko engaqhelekanga, ukusingatha ngokuzenzekelayo kwizibuko lokuphatha elingaqhelekanga, ukusetyenzwa ngesandla, kunye nokugcinwa kwempahla.

2. Iimpahla ezigqityiweyo Ex- warehouse

Emva kokuba i-WMS ithumele imiyalelo yokuthumela, i-automatic tray stacker ibeka iimpahla kumatshini wokuhambisa, emva koko umgca wokuhambisa i-annular uthumela iimpahla kwizibuko lokuhambisa elihambelanayo, ngepleyiti eyenziweyo, ileyibhile, ukuhambisa ibhanti, itayara elithe nkqo, i-telescopic ibhanti yokuhambisa ithuthwa ilori ukuze ihanjiswe.

Ukusetyenzwa kwepalethi engenanto: itreyi yetayara egqityiweyo emva kokwahlukileyo kwipallet, abasebenzi baya kuthumela ngesandla kwindawo yokugcina ngokuzenzekelayo

Kuyo yonke inkqubo yokulandelela ulwazi lwetayara ngalinye, ugcino kunye nolwazi lunokuba kulawulo oluzenzekelayo olupheleleyo, ukuphepha iimpazamo ezenziweyo ezibangelwa yimpazamo yokugcina kunye nokuhanjiswa, ukuphunyezwa okusebenzayo kokulandelelwa kolwazi, ukonga iindleko ezininzi zokusebenza kwamashishini, kwaye ukuphucula ukusebenza kwe theo peration.

Ixesha lokuposa: Sep-02-2022